presses

80 ÷ 1500 presses tonnage

moulding/injection quality control systems

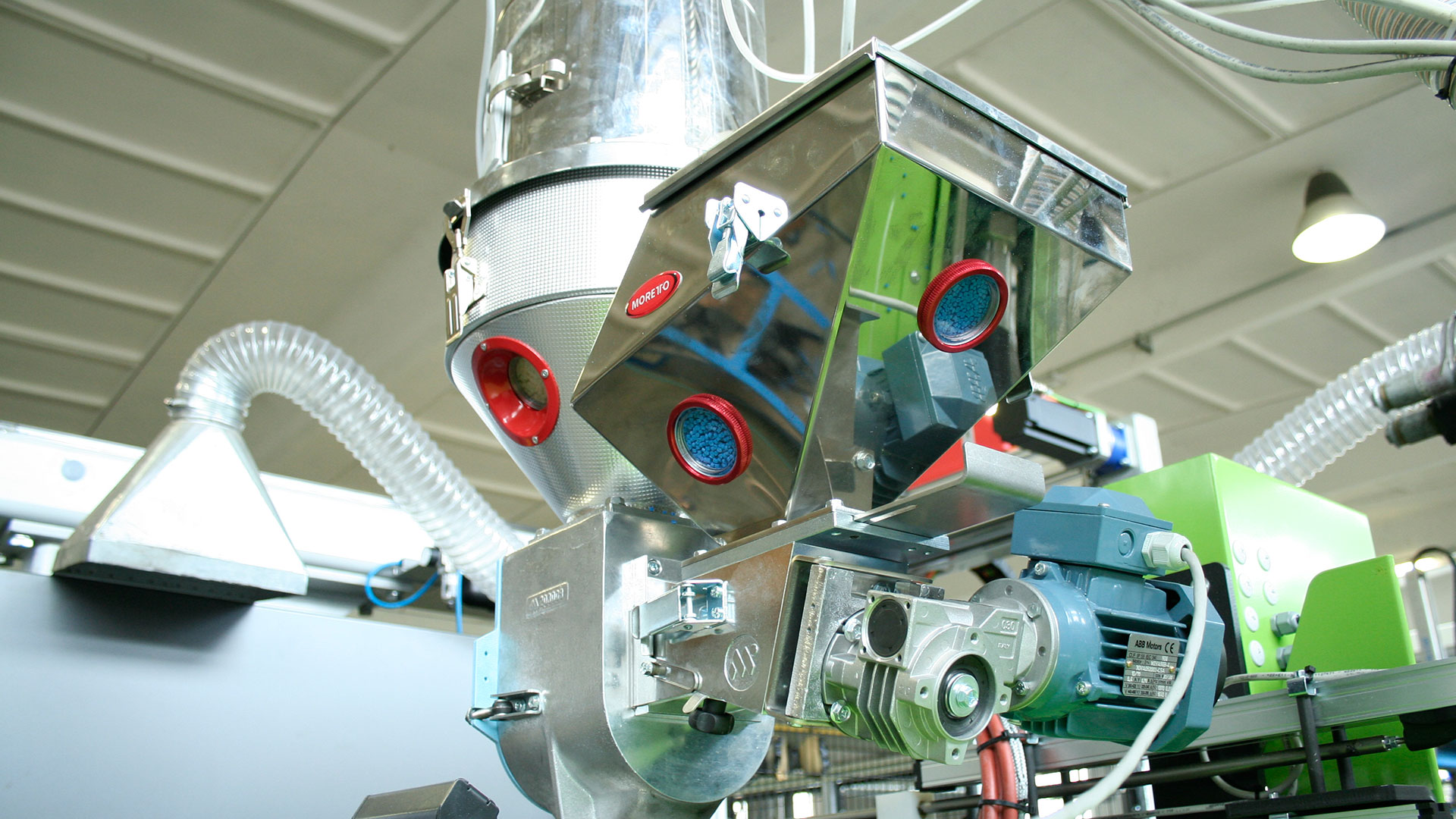

ENGEL®, ARBURG®, OIMA®, HAITIAN® and BATTENFELD® brand plants, technologically advanced and of latest generation are only some of the investments realised and dedicated to the highly automised production department, the presses, all powered by a centralised system, have Cartesian robots for the handling of the moulded products.

Currently, GelliPlast has injection presses with tonnage starting from 80t up to 1500t together with conveyor belts that end the production cycle handling the products towards packaging.

Moreover, the department is equipped with a large innovative dehumidification system that is generally used for polyamide articles in order to improve the mechanical and aesthetic characteristics of the products. The company can produce articles that require specific assembling therefore, it is has equipment for this type of processing.

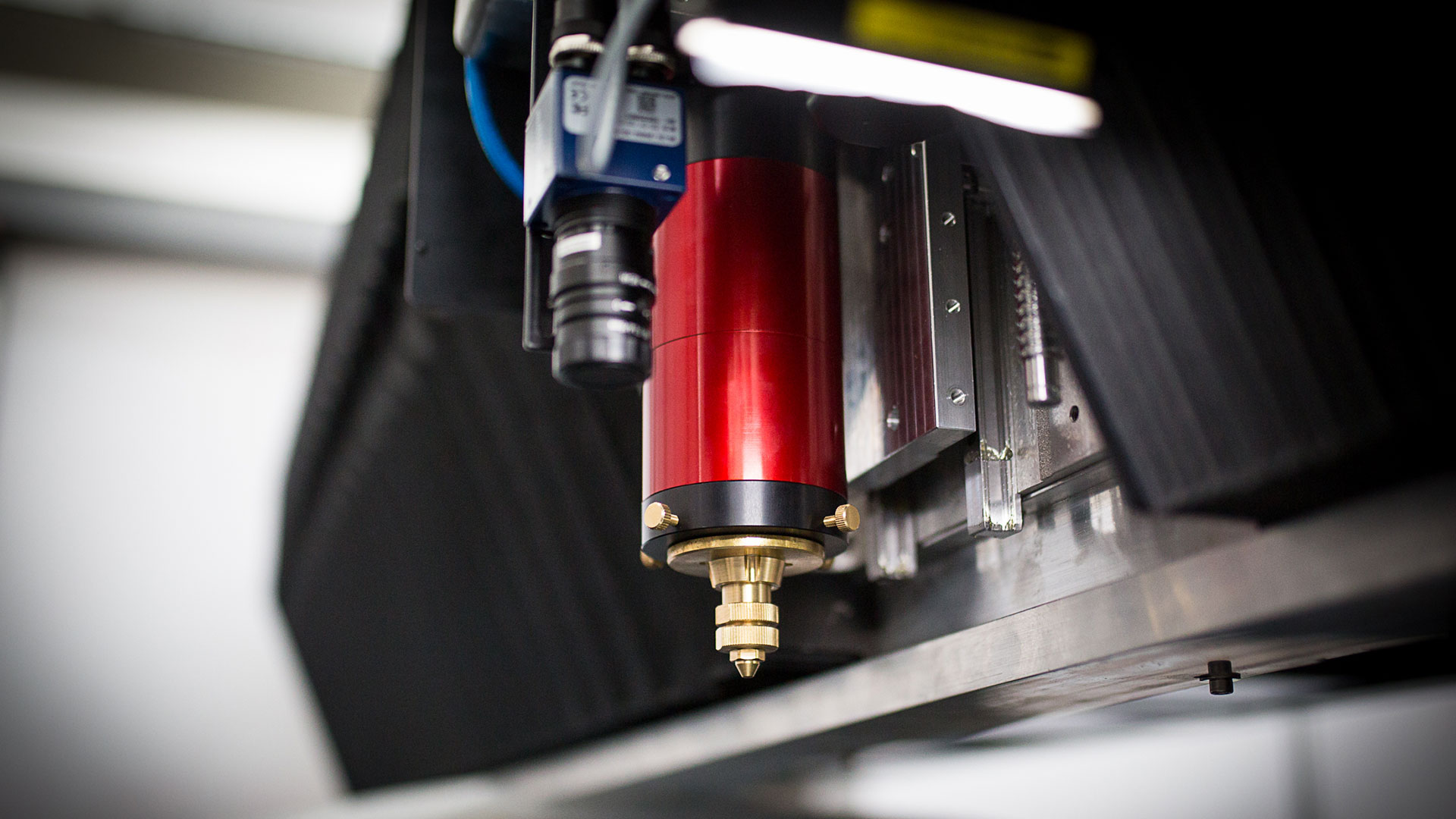

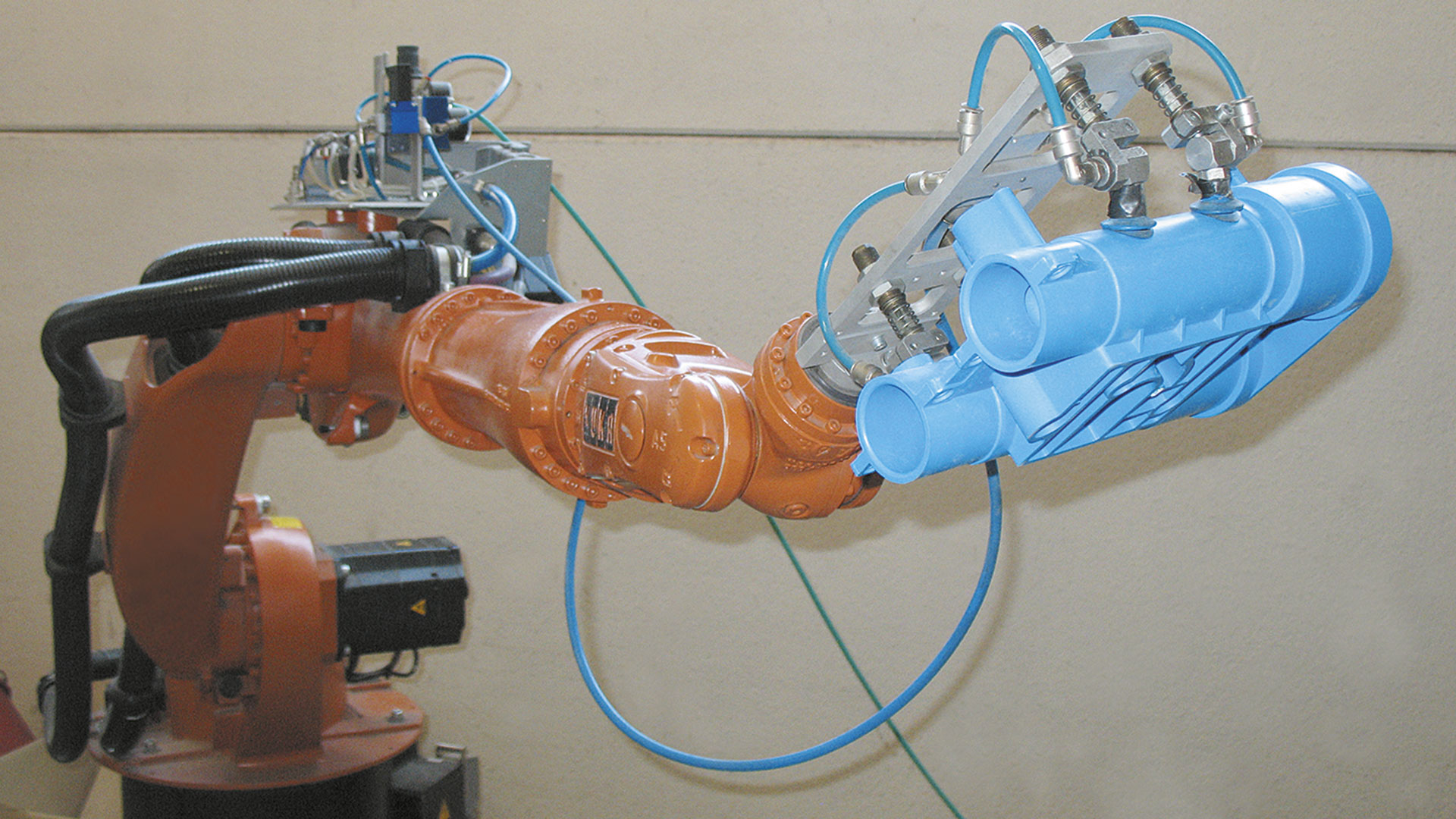

The department is completed by a highly automised line through the use of a KUKA® anthropomorphic robot, and CUTLITE PENTA® laser cutting centre dedicated to specific processing with high qualitative standards.

The processing waste and scraps are managed with immediate recovery processes or disposed of with reference to the laws in force, with disposal or recovery assignment to qualified companies.